|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| In the early seventeenth century concerns were being expressed in parliament about the granting of rather too many pipe making 'monopolies' or rights to produce pipes with associated powers to exclude others from the trade. Specifically, Oswald refers to a debate in the House of Commons on 24 November, 1601. He also quotes a letter (6) of 20 August 1618. The letter suggested that the situation as regards pipe making monopolies was so ridiculous that 'Archie the dizzard' or the king's jester might just as well be granted one given the ease with which they might be obtained! So it appears that this early link might not be quite what it seemed and certainly not what my father had in mind when he told me the tale. |

It is worth noting at this point that my grandfather, John Armstrong, may well have believed that the family's links to pipe making extended back to the early years of the industry. My examination of family papers brought to light a small newspaper cutting (sadly of unknown origin and undated) likely to have been produced in the 1920s. The article includes the following section. 'Clay pipes continue to be in great demand among miners and they prefer them short-stemmed. So says Mr. John Armstrong, who, in his little workshop in Marsh Road, Middlesbrough, makes clay pipes just as his family has done for 300 years'. I am uncertain as to whether John really believed the Armstrongs had been pipe makers for so long or whether he was exaggerating for the benefit of the reporter! In any case, I decided to carry out some research to see what evidence I could find to support the idea of a long association between the Armstrong family and pipe making.

Unfortunately, I have not been able to find conclusive evidence to support the idea that the Armstrongs were making pipes in the seventeenth century! However, I have established that there have been at least five generations of pipe makers in my family and I have presented the results of my research in the form of short biographies, concentrating on my own direct family line, with brief descriptions of the lives of their spouses included in the notes. I have also included short pieces on my great uncle and two of my uncles who were also involved in pipe making.

Members of the Armstrong family also married into other pipe making families; in particular the Hewitts. I have included short studies of pipe makers who were linked to the Armstrongs in this way. In addition, the notes provide information about other selected pipe makers and mould makers who may be of interest to the reader, as well as an acknowledgement of the sources I have used.

BIOGRAPHIES

1 James Armstrong (c.1795-1842)

James is the earliest Armstrong pipe maker I have identified. He lived in Stockton on Tees, Darlington and Derby. James was born in England around 1795 but his birthplace and exact date of baptism are uncertain. Whitehead's Directories for 1790 and 1795 refer to a John Armstrong who dealt in tobacco in Gateshead but he is unlikely to be related to James (7). The most likely baptism reference I have found so far suggests that James may have been baptised in Stokesley, North Yorkshire, a village very close to Stockton and Darlington, on 23 November 1794 (8). The early nineteenth century was a period of expansion for the tobacco pipe making industry when it became more geographically dispersed. There was an increase in the number of pipe makers operating in smaller towns serving a local market. James may well have moved from rural North Yorkshire to make a living as a pipe maker in County Durham.

Despite carrying out extensive research I have, so far, failed to establish how James entered the pipe making trade. It is possible that he was apprenticed to a master pipe maker but I have found no evidence to support this in the records I have investigated (9). I have also found no evidence to suggest that he followed his father into the trade or that he had any brothers who were pipe makers (10).

Parish registers show that he was married in Stockton on Tees to Sarah Hunter (11) on 4 February, 1819, while a resident of the parish. Evidence from directories confirms that clay pipes were being made in Stockton in the first half of the nineteenth century, so it is quite possible that James worked in the industry there (12), however, so far I have found no direct references to Stockton pipe makers earlier than 1841. James then moved to Darlington and worked as a pipe maker. The exact location of his workshop is unknown and the only other pipe maker I have identified as working in Darlington in the 1820s was Matthew Todd, who was recorded as a 'tobacco pipe maker', working in Northgate, in Pigot's directory for 1828-29. When his daughter, Mary Jane, was baptised in 1827, Matthew was recorded as tobacco pipe maker in the parish register for Darlington St. Cuthbert's. Matthew was born around 1806 so would have been too young to have been James's employer when the latter was making pipes in 1821. Around 1830, Matthew moved to Durham and was recorded in Pigot's Directory for 1834 as a tobacco pipe maker, working in South Street. He did not stay in Durham and in the 1841 census he was working in Westminster, London. Matthew did not remain a pipe maker and by 1851 he was living in Lambeth and described as a 'tailor's crayon maker'.

James and Sarah had four children, James born 1821, John 1822, Ann 1823 and Sarah 1825. James was recorded as a 'pipe maker' in the baptism registers for the parish of Darlington. Sadly, James (junior) only survived five months and James was to face further loss when his wife died in childbirth on 29 March 1825 at the age of 33 and his infant daughter, Sarah, died shortly afterwards on 2 October, 1825.

James then moved to Derby and continued to work as a pipe maker. He married Hannah Siddon on 11 February 1827 in the parish of All Saints, Derby (13). James was described as a 'pipe maker' in the marriage register. Benjamin Strong, a pipe maker based in Willow Row, acted as a witness to the marriage. James and Hannah had two daughters whilst living in Derby; Sarah in 1828 and Elizabeth in 1830. James was mentioned in Benjamin Strong's will, dated 12 July, 1830. Benjamin died on 22 May, 1835 and the will was proved in the Consistory Court of Lichfield on 12 April, 1836. James was referred to as the occupier of one of the two 'messuages' (dwellings, possibly including outbuildings) that Benjamin owned in court no. 7 in Willow Row (14). This confirms that James was in the employ of Benjamin during his time in Derby. Unfortunately, James was again to face tragedy, losing both Elizabeth and Hannah in 1831. At this time James was living in Agard Street, a location very close to Willow Row. Both Hannah and Elizabeth were buried on the same day, 17 February 1831, when Hannah was just 31.

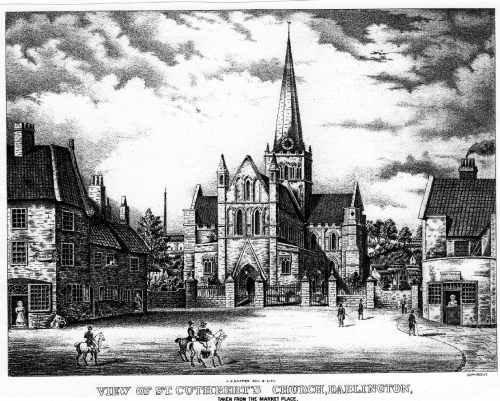

James then returned to Darlington where parish registers show that he was married again. His third marriage was to Ann Dunn (15) on 27 July, 1835. James was recorded in the 1840 poor law rate for Darlington as renting premises in Bank Top described as a 'house' from a landlord named John Farmer. It is interesting to note that James was not included in the 1833 list of voters for Darlington but had been allocated voting rights by 1840, indicating that he started his business sometime between these two dates. The property had an estimated gross annual rental of £4 17s 6d. To put this sum in the context of the day, we might compare it to the average annual wage of a general labourer. According to Williamson (1982), a general labourer in 1835 earned an average of £39 6s per year. The rent paid by James on his premises amounts to 12.4% of this figure. In the 1841 census James was recorded as a 'pipe maker', living in Bank Top with his wife, Ann, and his three surviving children. James died on 9 April, 1842, of unknown causes, aged 47. He was buried two days later in St. Cuthbert's churchyard.

St. Cuthbert's Church, pictured in 1843

2. John Armstrong (1822-1871)

John was baptised at St. Cuthbert's Church, Darlington on 28 April, 1822. Following the death of his father, John took over the pipe making business and presided over a period of growth. Demographics may have contributed to this expansion since John's time operating the business coincided with significant population growth in Darlington. The fact that he was able to retire in his forties may be the result of the success of the business but it may also have been due to ill health, especially since he was under 50 when he died.

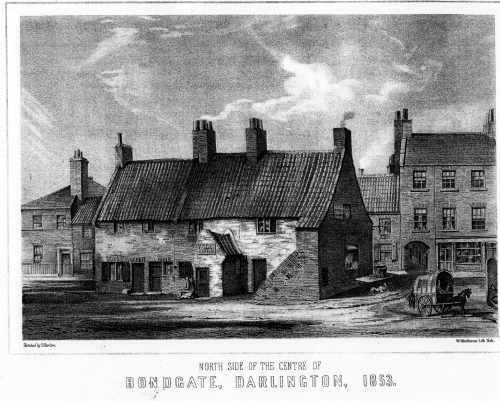

He was married to a widow, Mary Chaytor, nee James, in Darlington on 13 May, 1848. It is very likely that two of Mary's half-brothers, Richard and Joseph James worked for John (16). When his first son, John, was born in 1849, John's occupation was given as 'pipe maker' and he was living at 51, Bondgate, Darlington. A second son, William Hunter, was born in 1851 by which time he was recorded as living in Station Street. Sadly, William died in infancy. (It is likely that William was given the middle name of 'Hunter' in memory of his grandmother). John was recorded in the 1850 poor law rate as renting premises described as a 'house and pipe manufactory' in Station Street with an estimated gross annual rental of £12.12s. The landlord in this case was Thomas Oxendale. In 1860 the gross rental was £10 on property of the same description and the same owner. However, by 1870, John owned the 'house and pipe manufactory' himself for which the gross rental value had grown to £15. John also rented land and a shed with an estimated gross annual rental of £6 from H. K. Spark. This total rental value amounted to 41% of the nominal earnings of a general labourer in 1871 (using Williamson's data) and gives an indication of how the size of the business had increased since 1840.

John was recorded in the 1851 census as a 'pipe maker' and in the 1861 census as a 'pipe manufacturer employing four men, two boys and two women'. Kelly's 1857 Trade Directory referred to John as a 'pipe manufacturer' working at 23, Station Street and he was described as a 'tobacco pipe maker' in the 1858 Post Office Directory for Durham. The 1864 Slater's Trade Directory for Darlington included John as a 'Tobacco pipe maker' based at 26, Station Street. (It is interesting to note that the only other Darlington clay pipe maker recorded in directory, William Stuart, was also based in Station Street. Sadly, Station Street was demolished before 1887 to make way for an expanded railway station, which makes photographs difficult to find). John was recorded in the 1871 census as a 'retired pipe manufacturer'. By now he was living in Brunton Street and his son was in control of the pipe making business in Station Street.

Mary died on 1 December, 1866, in Richmond, North Yorkshire and she was buried three days later in Darlington. John was remarried to Sarah Jane Tutin (17) on the seventh of November, 1867. Sadly, John only lived four more years. He died of pneumonia on 15 December, 1871, aged 49. He was buried in West Cemetery on 19 December.

3 John Armstrong (1849-1917)

John was born in Darlington on 20 March, 1849, and spent his early years there. He took over the pipe making business from his father when still in his early twenties. John was married to Annie Hewitt on 20 December, 1870, in Darlington (18). Annie was part of a pipe making family herself and it is very likely that her father, James, worked at John Armstrong's workshop in Station Street (see Appendix 1).

John and Annie had ten children: John born 1872, Mary-Ann 1874, Minnie 1876 (sadly, she died at the age of seventeen months), Sarah 1879, Henry (Harry) 1881, a second Minnie 1884, Annie 1887, Lizzie 1890 and Jane and William (twins) 1893. John was recorded in the 1871 census, aged 22, as a 'pipe manufacturer employing four men, four boys and two women' in Station Street, Darlington. He was still working at this address when his first son was born in 1872.

It is likely that John faced problems with his business in the early 1870s and this necessitated a move to the Middlesbrough area for the family. At the time, the population of Middlesbrough was expanding very rapidly, creating more demand for pipes. If sales were depressed in Darlington, Middlesbrough may have offered him more opportunity to make a living. John's business in Station Street closed down and he became a journeyman pipe maker. The demise of John's business was consistent with the state of the industry as a whole. The number of individual firms fell significantly from the middle of the nineteenth century and the trade exhibited a strong tendency towards consolidation, with an increase in the concentration of large industrial concerns.

After leaving Darlington, the Armstrong family did not remain in one place for long and lived at a range of addresses in Middlesbrough, North Ormesby and Thornaby until the 1890s. John's first move was to North Ormesby and information on two of his children's birth certificates shows that he lived in Worsley Street in 1874 and Cromwell Street in 1876. By 1877, John's family were living in the Cannon Street area of Middlesbrough. They were residents of Walker Street in 1878 and John was recorded in the 1881 census as a 'pipe maker' in Pearson Street, Linthorpe. No direct evidence remains to show where John worked when he lived in North Ormesby and Linthorpe. However, Kelly's Directories suggest two possibilities. The 1872 directory gives one pipe maker, John Row, based in Linthorpe and the 1879 edition includes one Middlesbrough pipe maker, T. Underwood, working in Wilson Street, an address very close to where John was living in 1878.

It appears from birth certificate evidence that Annie returned to Darlington periodically where her mother was still living, and Henry, the second Minnie and Annie were all born there. John himself must have returned there for at least a short period of time and was resident in Station Terrace, Darlington, in 1879.

Their children's birth certificates show that from 1887 John and Annie were based in Thornaby, living first in Frederick Street, later in Nile Street and then Carpenter Square. On the twins' birth certificates (December 1893), John was described as a 'pipe manufacturer-journeyman'. In the 1891 census, John was recorded as a 'pipe maker' living in Nile Street. It is not clear where John was working at the time although evidence suggests that he might have worked in Britannia Street for an Irishman called Farrell Prior.

Farrell Prior operated a pipe making business at this location for many years. This is recorded in Ward's and Kelly's Trade Directories during the period from 1889 to 1913. The 1881, 1891 and 1901 censuses also described him as a pipe manufacturer based in Britannia Street. Farrell was the only pipe maker recorded in the Thornaby area and the three addresses where John lived were all very close to the location of his workshop. John's son, John (b.1872) was later to operate in the Britannia Street pipe works formerly used by Farrell Prior. An extract, written in 1937, but describing life in Thornaby in 1880, makes reference to Farrell Prior (19). He was described as the owner of a 'small smoking clay pipe factory' who sold pipes cheaply to local publicans and was even inclined to give a free pipe to any man who asked for one! It is worth noting that Farrell had been preceded as a pipe maker in Britannia Street by James Kitching. James was recorded in directories as operating there in 1851 and 1856 (20).

From 1900 to 1914, John frequently spent time in the workhouse. He was regularly admitted to the Middlesbrough Workhouse and also stayed in the Stockton Workhouse. He was resident in the Middlesbrough Workhouse on the evening of the 1901 census and he was recorded as an inmate in the Stockton Workhouse in the 1911 census. Times were hard for the Armstrong family and the youngest four children had spells in the Middlesbrough children's home from 1900 to 1904 (21). Three of John's daughters, Minnie, Annie and Jane married in Eston and John was resident at the home of Annie (who married George Henry Myers in 1910) when he died of heart failure on 11 June, 1917. John was buried in Eston Cemetery 5 days later.

4: John Armstrong (1872-1943)

John was born in Darlington on 9 April, 1872, but moved away as a small child, spending his early years with his parents in Ormesby, Middlesbrough and Thornaby. John continued pipe making, first as a journeyman, then as a master. John married Jessie Teasdale in Thornaby on 19 May, 1894 (22). An old family tale of doubtful authenticity suggests that John and Jessie's honeymoon consisted of a day trip to Roseberry Topping in a pony and trap. If this story were true then it would appear that money was tight! Further evidence to suggest that this might be the case is provided by surviving documents showing John and Jessie's credit purchases from William Little and Son, Stockton on Tees, soon after their marriage: '1 bedstead 25/-, 1 mattress 8/6, 1 table 12/6, 4 chairs 5/6, 1 hearth rug 7/-, 1 set of irons 2/9 and 1 tidy 3/6'. Altogether these items cost £4 1s 3d, but John and Jessie only put down an initial payment of 6/-, taking almost a year to pay the whole debt. They decided to purchase a sofa for £2 2s once they had completed their first set of payments, taking 6 months to settle this account.

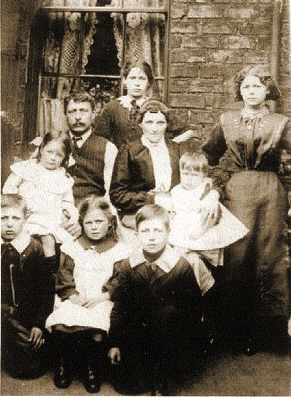

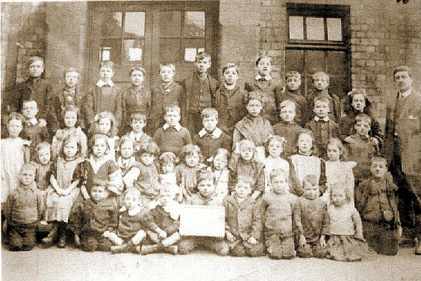

The Armstrong family, shortly after moving into Farrer Street. John and Jessie with their children, clockwise from top: Lena, Annie, Fred, Harry, Minnie, Jack and Bella. John and Jessie had ten children, Annie born 1895, Lena May 1896, John William (Jack) 1898, Robert Henry (Harry) 1900, Jessie Fontien 1902, Albert Edward (Eddie) 1904, Minnie Hannah 1906, Isabella 1909, Frederick George 1911 and Alfred (Alfie) 1913. Sadly, both Eddie and Jessie died in childhood, in 1911 and 1912, respectively. Marsh Road School, Cannon Street, c. 1912. Minnie is pictured 2nd row, 4th from left. Harry is pictured 3rd row, 6th from left.

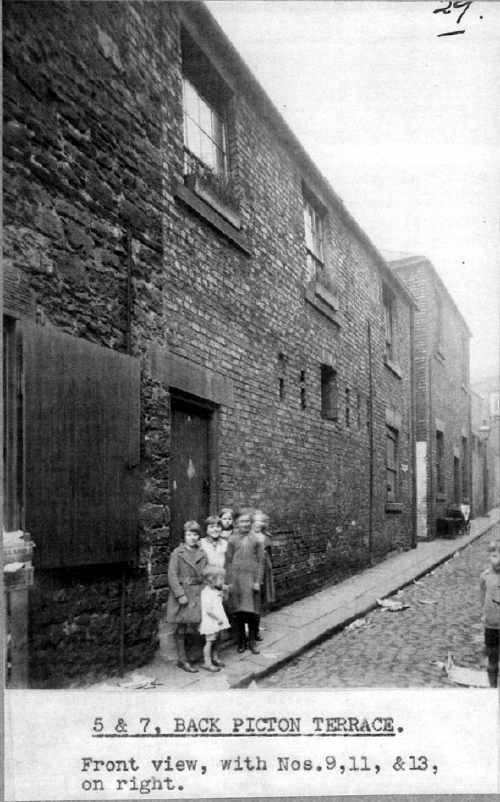

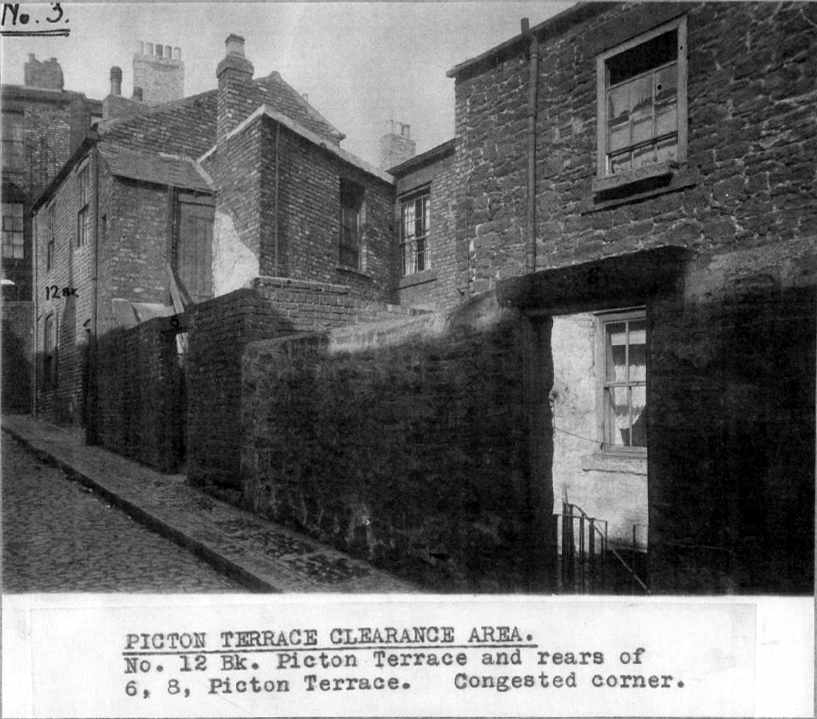

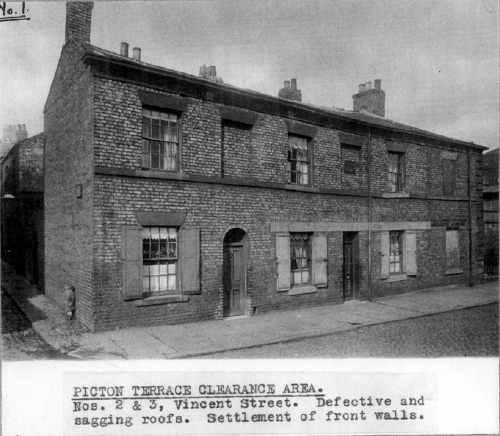

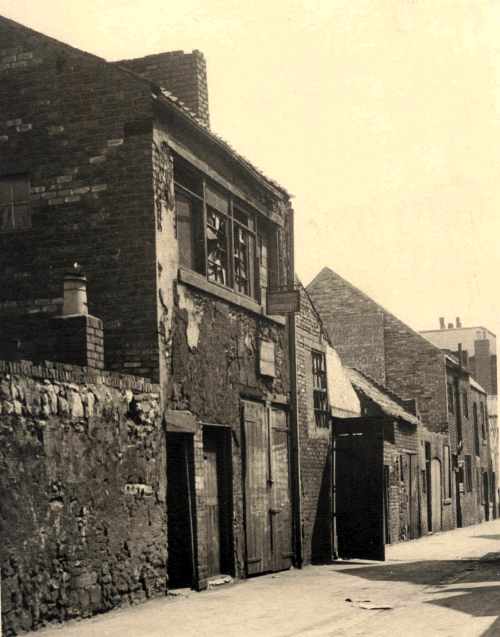

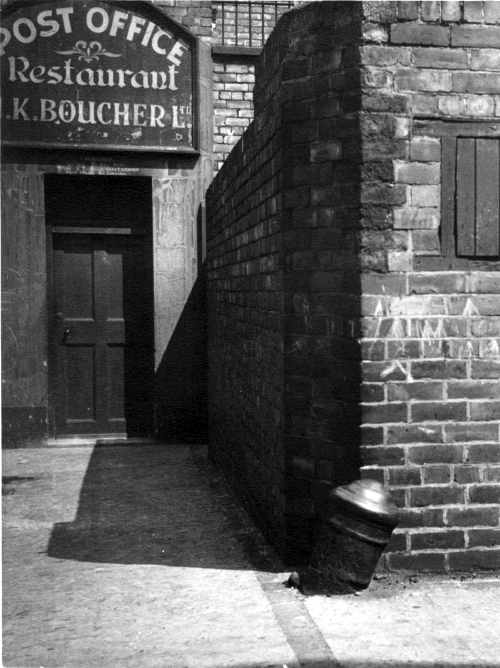

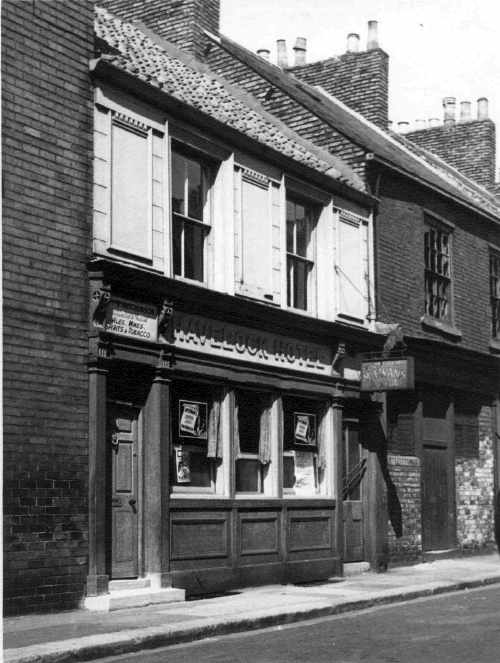

John made pipes at a range of locations including short periods in Newcastle and Sunderland. The family lived at 18, Picton Terrace, Newcastle, from April 1896 until May 1897. Picton Terrace only survived until 1935 but, immediately prior to its demolition, corporation photographers recorded the appearance of the area. A number of the photographs taken are included in Appendix 4. Kelly's Directory for Newcastle in 1896 gives three possible employers for John (23). I have no direct evidence to connect John with any of these businesses but his most likely place of work is Nugent and Company, based at 3 Vincent Street, a road adjacent to Picton Terrace. A 1930s photograph of this property is also included in Appendix 4.

The family lived at 42, Nile Street, Sunderland, from 1906 to 1912 (see Appendix 4). Until 1909, John worked as a journeyman pipe maker and I cannot be sure of the name of his employer. However, Kelly's Directory for 1906 gives the address of the Wear Pipe Manufacturing Company as Back Nile Street (24) so it is very possible that John worked there. According to Helme, John set up his own business in Coronation Street in 1909, an address very close by (25). The birth certificate issued in 1911 for his son, Fred, confirmed John's status as a master pipe maker. The census taken later that year recorded John as an 'employer' working 'at home'. Helme also mentions the comprehensive range of moulds owned by John (see Appendix 6) and even credits him with the invention of a porous clay pipe plug especially designed to aid the 'wet smoker' (26). Helme is also able to provide a quote directly attributable to John. Apparently, John would often state 'a common clay pipe is the sweetest smoke of all' (27).

Although John ventured north for these short spells, he spent most of his working life in Middlesbrough and Thornaby. John was recorded in the 1891 census aged 18 as a 'pipe maker' while living with his parents in Nile Street. When he married in 1894 he was resident in Prince Street, both addresses in Thornaby. Following his return from Newcastle, John again lived in Thornaby and the 1901 census reported him as a 'clay pipe maker' living in Lumsden Street. It is quite likely that John worked at Farrell Prior's workshop when resident at these addresses, prior to his move to Sunderland.

In 1912 the family left Sunderland and moved to Farrer Street, Middlesbrough, where John continued his pipe making business. Surviving documents suggest that the workshop was probably based at 28, Hardman Street, a nearby location in the Cannon Street area for which John paid a weekly rent of 2s 6d. The 1918 rate book for this property gives the owner as Annie Cersley and states that the estimated gross annual rental was £3 15s and the rateable value was £3.

John pictured in uniform during World War One

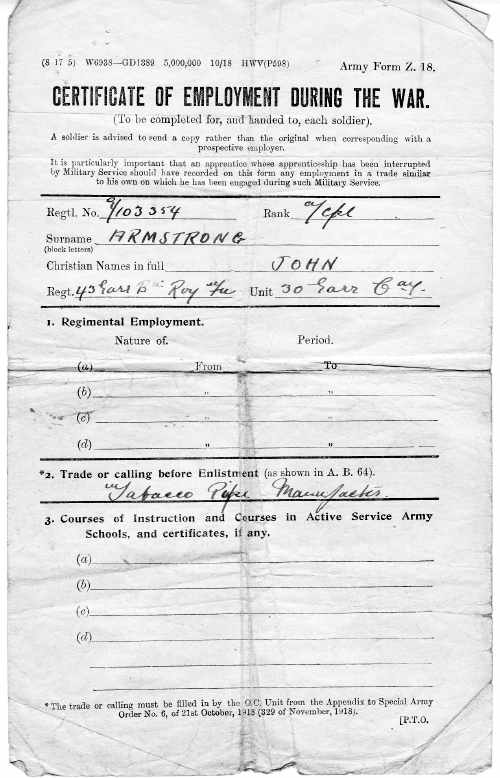

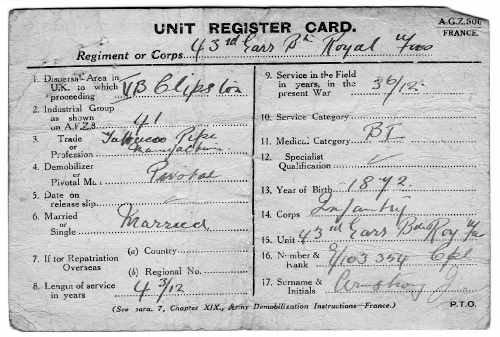

The outbreak of war meant family life was soon disrupted. John enlisted on 30 October, 1914, and remained in the armed forces until 12 March, 1919. Of this, three-and-a-half years were described as 'in the field'. John spent the majority of the war serving in the 9th Battalion of the Yorkshire Regiment. After initial training in southern England, the battalion embarked for France in late August 1915. It was part of 69th Infantry Brigade, which itself was one of the brigades of the 23rd Division. As part of the 23rd Division, the 9th Yorkshire Regiment was involved in several of the most significant battles of the Great War. During his time in France John fought in the campaign on the Somme, in particular the capture of Contalmaison in July 1916 and Le Sars in October 1916. The 23rd Division was then transferred to Flanders and the 9th Yorkshire Regiment took part in the Battle of Messines, including the assault on Hill 60, in June 1917. The 23rd Division was then involved in heavy fighting at Ypres from the end of July to mid October 1917, in particular the battles at Menin Road Ridge, Polygon Wood and Paschendale. However, it seems likely that around the time of the Battle of Menin Road Ridge, late September 1917, John was transferred to the Labour Corps. John was, by then, 45 years old and no longer required to fight as a front line soldier. However, he had no doubt seen more than his fair share of action by this stage (for a detailed account of the 23rd Division during the Great War see 'The 23rd Division 1914-1919' by Lieutenant-Colonel H. R. Sandilands). John is likely to have been part of 878 Company when serving in the Labour Corps. This company was a Garrison Guard Company and used to guard areas of military significance such as dumps and railway lines. It would also have been used for anti aircraft work. In April 1918 it was one of the companies that formed the Provisional Guard Battalion. (For a fully researched account of the activities of the Labour Corps see 'No Labour, No Battle' by John Starling and Ivor Lee. I am very grateful to Ivor Lee for providing the above transfer date of September 1917 and other help with my research). These companies later became the 43rd Garrison Battalion of the Royal Fusiliers, which was used to man quieter areas of the front. John finished his service with this battalion and reached the rank of corporal. His company commander gave him the following reference: 'This N.C.O. is of good character and his work whilst with the unit has been quite satisfactory.'

Informal group shot showing soldiers of the 9th Yorkshire Regiment taken during World War One. John is standing on the far right of the back row.

John applied for a government grant to assist with restarting pipe making after the war. In his application he gives the normal value of his stock as £75. He states that the value of his two pipe kilns was £25 (it is unclear whether this figure is for each one or the pair). His benches, racks and boards were valued at £3 and his pipe moulds at £5. (Unfortunately, the quantities to which these sums refer were unspecified. Indeed, these figures may refer to the sums John estimated he would have to spend on these items from any financial assistance he might receive). He gives the cost of pipe clay at 53 shillings per ton with carriage to pay.

His eldest son, Jack, was able to keep the business running during the Great War until he was also called up in March 1917. However, after this date, the business ceased to operate until after the War. John states his problems clearly in his application for assistance, 'pipe moulds are one mass of rust and, owing to the premises being closed, the pipe kilns have been pulled to pieces by boys climbing over the walls.' John goes on to make his case '... I am no use to any other trade but my own'. He considers that without pipe making he is, 'without any means of livelihood.' A further justification of his request comes in the following statement concerning his need for funds, '...to enable me to get started without delay with my business which was a growing one and in time would have employed a number of hands. The premises are in a terrible state owing to bad usage which has arisen during my absence in the army'. If John's description of his business as a 'growing one' was true then the decline described in a newspaper article about John's business published in 1928 (see below) had not yet taken hold. However, John may simply have been putting an optimistic slant on his application!

John's pipe making premises were located in Britannia Street, Thornaby, in the early 1920s. John was recorded as operating as a pipe manufacturer in Britannia Street in Kelly's Directory for 1921 and 1925. (A point worth noting is that John was the only clay pipe maker listed for the whole of the North and East Ridings in the 1921 and 1925 directories. When we consider that directories from the late nineteenth century feature many pipe makers the declining size of the industry in the area is readily apparent).

John's granddaughter, Lena Ross (born 1919), remembers her mother, Annie, telling her about the history of the workshop. Annie recalled that it had been used by Farrell Prior and it's likely that John took over the lease from him when he retired from pipe making. The 1909 rate book for Thornaby confirms Farrell Prior as resident at 31, Britannia Street, a property with a rateable value of £6 10s, and gives the owner of the house as Mary Paterson. The rate book also shows that Farrell's nephew, Michael Brannan, occupied a property described as a 'pipe shop' in Britannia Street. There is no number assigned to this shop so it may well have been situated at the rear of Farrell's house. Lena's own recollections tend to support this idea.

Although she was very young at the time, Lena has many memories of her grandfather's premises in Britannia Street. After their marriage, Annie (John's eldest daughter) and her husband, James Carson, a riveter, lived at Farrell Prior's former address. Lena believes that her grandfather's connection to Farrell Prior helped her parents to obtain the lease on the property. There was access from the back of the house into a large yard where John's workshop was situated. The premises were big enough to house pipe kilns with the actual pipe making process being carried out on the first floor. Lena recalls the wooden staircase that provided access to this part of the building. Around half a dozen benches and the equipment required for pipe making were set out on this upper level, the lower level probably being used for storage. Lena remembers visiting the workshop and being given bubble pipes to play with. She also remembers being given some of the red stickers used to mark the pipes. One rent book for a 'pipe factory', unfortunately undated, has survived. The landlord's name on this book is M. Paterson, which tends to suggest that Mary Paterson was still the owner of the workshop in the early 1920s. The rent payable was 7s 2d per week. The rent book was only used for a short time but it is nevertheless heartening to read that John managed to stay out of arrears!

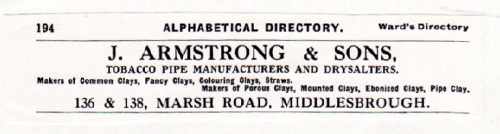

John Armstrong's advertisement in Ward's Directory 1926-27

John then changed the location of his workshop (Lena remembers the outbuilding behind 31, Britannia Street being used as stables after he left) and ran his business from Marsh Road, Middlesbrough. He was recorded in Ward's Trade Directories as running a pipe making and dry salting business in Marsh Road from 1926-1937, specialising in numerous types of clay pipes. Rent books show that he started renting the property in 1924. A weekly rental of 3s 6d was payable from 1924 to 1930. The rent then fell slightly and was set at 3s 4d until 1934. For the last 3 years that John rented Marsh Road he had to pay a slightly higher rent of 3s 7d per week. Given the depressed state of demand for pipes it is not surprising that John's rent books show that he was in arrears for much of the 1930s. The Marsh Road workshop was essentially two adjoining terraced houses. In the Ward's Directory of 1926-27, John's business address is given as 136-138, Marsh Road; however, from 1928-29 the address is given only as 136, Marsh Road. 138, Marsh Road seems to disappear as an address in its own right and does not appear at all in the 1929 rate book for Middlesbrough. The book shows that 136, Marsh Road had an annual rate bill of £2 12s 6d and it was owned by R. and H. Holder. John also rented a warehouse in Chapman's Yard, Middlesbrough, between April and July 1939 at a weekly rental of 3 shillings a week.

Another of John's granddaughters, Raye Pickering, born 1928, recorded her memories of Marsh Road in February 2008, 'I remember being taken to what was known as the 'pipe shop' in Marsh Road in about 1937. I probably went in my father's car which I have always remembered as 'UP6348'. My father, John William, was then known as Jack [see biography 7]. The building was essentially two adjoining houses, not even knocked into one, just out of one and into the other! There were no floor coverings, just wooden floors and stairs. Upstairs in one room there were lots of shelves with racks of pipes. There were several huge round clay containers called saggers. The clay pipes in them were arranged with the bowls towards the outside and the pipe stems towards the centre like spokes of a wheel.

In the area near the pipe shop there didn't seem to be any other properties - lots of big puddles with bricks in them and desolation. My dad's brother, Uncle Harry, [see biography 8] worked there and he rode a big, black bicycle with a metal carrier on the front. He and his wife and son lived in North Ormesby' [a part of Middlesbrough bordering the Cannon Street district].

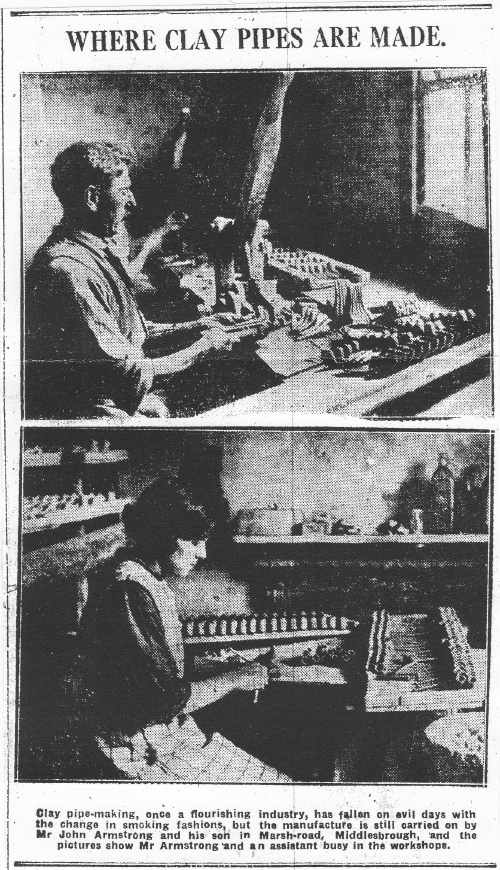

In 1928 John's business was the subject of two newspaper articles. The first is shown below. John is pictured in the foreground of the upper photograph. John's son, Fred was working at the same bench and his arms are just visible behind John. The 'assistant' shown in the lower photograph is very likely to be Minnie, John's daughter. Clearly the demise of the clay pipe making industry generated some interest!

The article featured in the North Eastern Daily Gazette on 2 July, 1928. The second piece (28) followed the same theme and highlighted the decline of the industry by noting that J. Armstrong and Sons was considered to be the 'only concern of its kind between Sunderland and Manchester.' In the piece, John laments the decline of pipe making and the fact that sales are well below his capacity output of 3000 pipes per day. 'It is not only the popularity of the cheap cigarette that is killing the clay pipe', he said, 'it is a certain snobbishness that is making smokers drop an old friend. How many men do you see smoking a clay in the street today? Very few and yet a large number of smokers only prefer a wood pipe because of the look of the thing'. Given low demand, prices were correspondingly depressed; in those days the selling price of pipes was only 1s 2d per gross and 2s 4d for the fancy clays.

Several postcards sent by Ralph Barton and Son (a firm of salt and whiting merchants) based in Hetton-le Hole, relating to orders of pipes from John, have survived. One such card, dated 10 May 1932, relates to a purchase of '30 gross T.W. pipes' (see section below on John William Armstrong). A second (probably contemporary) card refers to an order for '100 gross of assorted pipes'. An undated letter, possibly written around the same time, was sent to John by Mrs E. Layfield of Harrogate. In the correspondence she ordered a gross of 'miners' pipes', having been unable to obtain them from 'Dick Bros'.

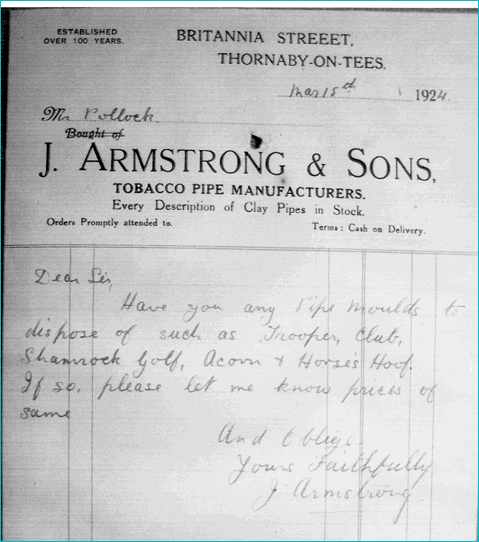

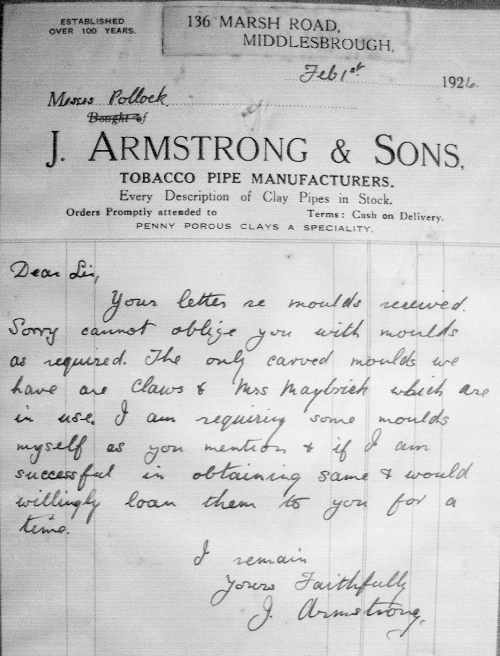

Surviving documents show that John corresponded with Pollocks of Manchester. In 1924, he contacted them to find out if they had particular moulds for sale. John wrote, 'Have you any pipe moulds to dispose of such as Trooper, Club, Shamrock, Golf, Acorn or Horse's Hoof. If so, let me know prices of same.' He was also prepared to lend pipe moulds to Pollocks if he had them to spare. In 1926 he wrote, 'your letter re moulds received. Sorry cannot oblige you with moulds as required. The only carved moulds we have are Claws and Mrs Maybrick which are in use. I am requiring some moulds myself as you mention and if I am successful in obtaining same I would willingly loan them to you for a time'. The headings on these letters state that John's business had been 'established over 100 years'. I know that James Armstrong was making pipes in 1821 (possibly even earlier) which tends to confirm John's statement (see Appendix 2), although he and his father spent much of this time working as journeymen pipe makers.

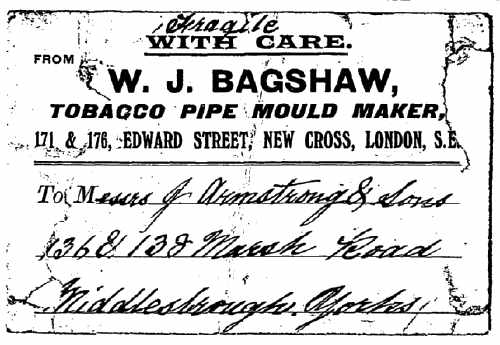

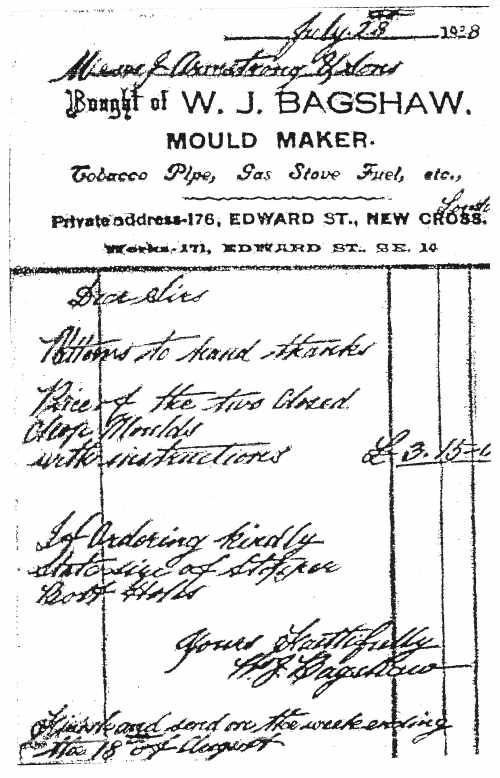

John and his son also purchased pipe moulds directly from mould makers. This is confirmed by an address label and quote bearing the name of Walter. J. Bagshaw, a London mould maker (29). The quote relating to two moulds, with instructions, for a total price of £3 15s, dates from 1923 (or 1928). The label is undated but was sent during the time John was working in Marsh Road (see Appendix 2). A surviving receipt, dated 12 March 1932, shows that John's son, Jack, purchased an individual mould from Hugh Herriot, a Glasgow mould maker (30) for £1 7s.

A receipt dating from the time John and his sons were working in Marsh Road (31 January 1934) and also sent to Jack, confirms that the business was buying clay from The North Devon Clay Company (31), a firm based in Torrington. The document referred to an order for 6 tons of best cutty clay at 33/6 per ton.

The Armstrong family lived in Farrer Street until the 1930s and then moved on.They spent some time in Hartington Road and then Union Street. John's final move was to Stowe Street in 1937. Number 32 was to be occupied by an Armstrong until his daughter-in-law, Mary, moved to York in 2004. Surviving correspondence from the 1930s suggests that John looked for several ways to bolster his income during the declining years of his business. Postcards sent in 1935 from 'The Pottery', Bridge End in Yarm, provide evidence that John was employed by them to assist with the pottery making process. One specific request was written as follows,' all being well we shall light our kiln with glazed ware on Tuesday night. I shall be obliged if you will come up on Wednesday morning and finish it off.' John was also prepared to travel to find work as a pipe maker in the late 1930s. John worked on the premises of Ralph Barton and Son from 1939 until his death (32). John stayed in Hetton-le-Hole when making pipes there and made periodic visits home.Correspondence confirms that this venture required the transportation of moulds and tools from Middlesbrough.After John's death, his son Fred travelled to Barton and Son's and brought back the equipment.

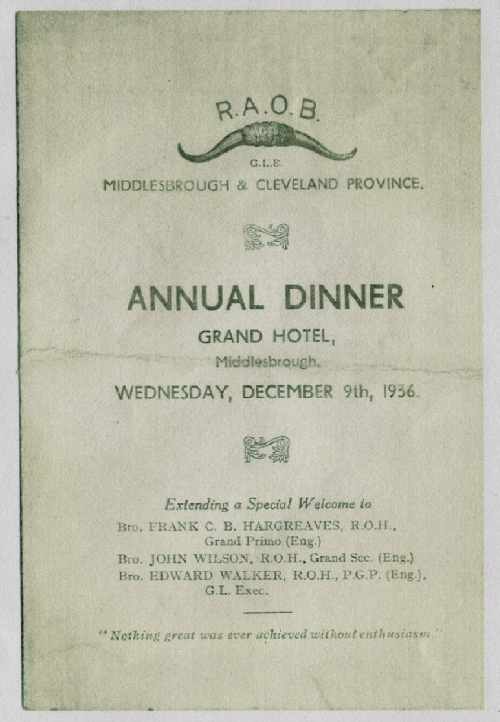

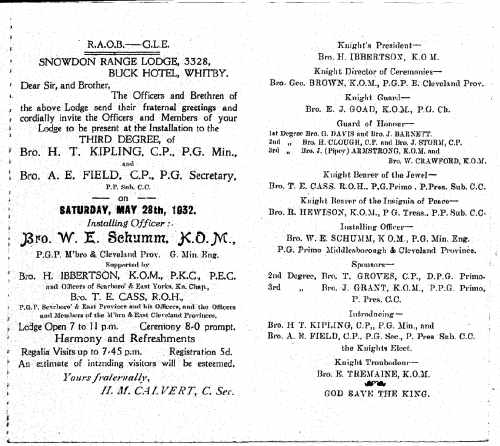

John had a reputation as a heavy drinker and a harsh father, especially in early life, but has been described as a 'jovial grandfather' by Lena, his eldest grandchild, so he is likely to have mellowed in his later years. John was making pipes in the workshop behind her parents' house until she was seven years old and even after he started pipe making in Marsh Road she remembers him as a regular visitor to their house, when her mother would provide him with one of his favourite meals-a tin of crab!John was a member of the Royal Antediluvian Order of Buffaloes (RAOB) for at least 30 years and held high 'rank' in the 1930s. It is interesting to note that John's nickname of 'Pipey' even appeared in some of their official programmes! John's importance is clear from the extensive collection of RAOB souvenirs gathered by his son, Fred (see Appendix 5). The organisation probably provided John's business with a good level of custom since clay pipes were used in their ceremonies (33). John joined the Fellowship for Freedom and Reform in 1930 (This was a society committed to opposing prohibition so membership seems consistent with his reputation!).

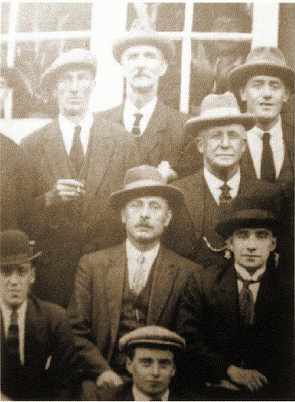

Group photo of ROAB members, taken in the 1930s. John is pictured second from the left on the second row.

John's family provided an excellent source of labour for his business. John William (Jack) and Harry were also involved with making and selling pipes and Frederick George concentrated on the manufacturing process. John's daughters, in particular Annie and Minnie, also helped in the factory. Rather romantically, the 1928 newspaper article gives an interesting insight into John's view that dexterity with clay was an inherited characteristic and one which was a particularly noteworthy feature of his son, Fred, then 17. After more than half a century of clay pipe making, John died on 10 January, 1943. Lena recalls the circumstances of his death. John had just returned from working in Hetton-le Hole and was on his way to a meeting of the RAOB but had a heart attack whilst in Pearl Street and never reached his destination. On 14 January John was buried in Acklam cemetery.

5: Frederick George Armstrong (1911-1990)

Frederick George (Fred) was born in Sunderland on 15 February, 1911 and moved to Middlesbrough as a small child. He followed the family pipe making tradition and exhibited great talent with clay. He gained the nickname of 'The Sutcliffe of the Clay' (after Herbert Sutcliffe, the Yorkshire and England batsman.) This skill was recorded in the newspaper article of 1928.Fred feared and admired his father and aimed to follow in his footsteps. He also joined the RAOB and gathered an extensive collection of memorabilia.

Fred attended Marsh Road School and started pipe making when he was fourteen but by the time he was twenty-four, the business was in decline and he left to find alternative employment. Fred was interviewed in the Northern Echo in 1972 following on from an earlier article in 1963 featuring his elder brother Jack.

Fred, photographed for the Northern Echo article, demonstrating the pipe making process in the back yard of 32, Stowe Street

Both men considered the work to be very hard and conditions dirty, damp and smoky. 'It was very hard work,' remarked Fred, 'because everything had to be done by hand. We had the clay sent up by rail from Cornwall and we had to collect it from the goods yard. I made 30 gross of pipes a week for 30 shillings and at one time they were sold for 1s 2d a gross but they are more than twice that price each now.' Fred recalled that, 'some of the moulds have been in the family for well over 100 years.' At the time he had dozens of moulds in storage and each one was different. 'They were made in London and cost about £2 each in those days,' noted Fred, who remembered making 300 casts an hour in the Marsh Road factory. 'We sold the pipes locally to pubs, hotels and shops and we made a special short-stemmed pipe for the Durham mining villages. The miners liked a short-stemmed pipe because they used to carry them in their waistcoat pockets. Altogether I think we had a range of about 100 different pipes because even with clay pipes there were fashion fads and you had to keep abreast,' added Fred.

Fred had several jobs after the business folded just before Second World War but spent 29 years as a postman. He enjoyed his job (and knew all the old streets of Middlesbrough) but often talked about his time as a pipe maker. Despite the fact that he obviously considered it to be very hard work, he certainly looked back on it nostalgically. He was very proud of his reputation as an expert manipulator of clay and of the long family tradition of making pipes. He enjoyed telling me about pipe making when I was a small boy, in particular describing the historical figures commemorated by having their image on the bowl of a clay pipe. His favourite was certainly General Gordon of Khartoum (34). The mould used for making this particular pipe and one celebrating Queen Victoria's Diamond Jubilee in 1897 are the two moulds I remember most clearly from childhood. I can also recall my father showing me moulds with a cricketer and football design. All these moulds were part of a small selection of equipment donated to Preston Hall Museum in the 1970s, where they remain today (see Appendix 6).

Fred would also talk fondly of his time in the RAOB, an organisation he referred to as the 'Buffs'. He treasured the medals and certificates he received from them, quite possibly because of the link between the RAOB and his own father. Fred was a contented family man.He enjoyed living in Middlesbrough and was a lifelong fan of Middlesbrough FC. His favourite players were Wilf Mannion and George Camsell and he preferred the football of the 1930s to the rather more tactical game popular in the 1970s.

During World War Two Fred served in the RAF Regiment. He enlisted on 18 July 1940, reaching the rank of leading aircraftsman and, as part of the RAF's Second Tactical Air Force (2TAF), Fred saw overseas service in France, Belgium, Holland, and Germany after the D-Day landings. Fred's squadron leader gave him the following reference:'A steady, hard-working man who can always be depended upon to do his best under all circumstances. He is a good influence on his fellow men.' Fred left the RAF on 14 November, 1945 and returned to civilian life. Fred married Hannah Mary Weatherill on 16 June 1951 (35). They had one son, Philip, in 1958 (the author). Fred died of pneumonia on 5 February, 1990, and is buried in Acklam Cemetery.

Fred was well liked and respected and his wife aptly describes him as a 'gentle and honourable man'. Fortunately, he was also meticulously well organised and had the foresight to store away the family pipe making equipment carefully. It remained in storage for 50 years and is currently in use in the pipe making museum in Broseley, Shropshire, where Rex Key continues to make 'Armstrong pipes' in the traditional way (see Appendix 6).

6 Henry (Harry) Armstrong (1881-1948)

Henry was the second son of John (b.1849) and followed the family tradition of pipe making, at least, in his early working years. He was born in Darlington on 4 July 1881. In the 1901 census he was recorded as a 'tobacco pipe maker'. Henry's father, John, was in the workhouse and he was described as a 'boarder', living with his sister, Mary Ann. Mary Ann had married John Hope (1897), a shipyard riveter, and had two children at the time, Thomas (2) and Nellie (9 months). The family were living in Thornaby at the time of the census, so it is possible that Henry was working with his brother, John, in Farrell Prior's workshop when the census was taken. Henry did not continue as a pipe maker. In the 1911 census his occupation was given as a 'labourer' and at the time of his marriage he was described as a 'platelayer at ironworks'. Henry married Frances Cammack, daughter of George Cammack, an electrician in Middlesbrough on 11 July, 1914.

It seems likely that Henry fought in the Great War and was photographed in uniform alongside his elder brother, John (pictured on the left). After World War One, Henry continued to live in Eston with his wife and children. John was born in 1919, Betty in 1921 and Neville in 1923. During this period Henry's occupation was a 'blast furnace slagger'. Later in life Henry moved to Kent and worked as a council labourer. He died in Penge on 21 August, 1948 but his final resting place was in his home area. Henry was buried in Eston Cemetery five days after his death.

7: John William (Jack) Armstrong (1898-1971)

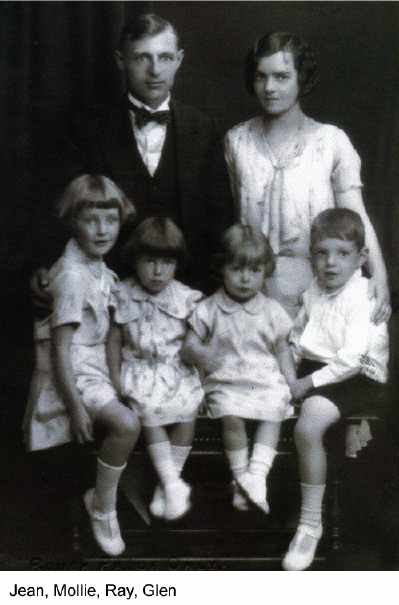

Jack was the eldest son of John (b.1872) and worked as a pipe maker until the late 1930s. He was born in Thornaby on 29 December, 1898. On 26 July, 1921, he married Mary Forrest (b.1896), daughter of Robert Forrest, a grocer. Jack's occupation was given as 'clay pipe maker' on the marriage certificate. They had five children, Jean born 1923, John ("Jack") Forrest 1925, Molly 1926, Raye 1928 and Glen 1932.

Jack and Mary (known as Molly) on their Wedding Day, 26 July 1921 Jack and Mary with four of their children.

In an article in The Northern Echo published in 1963, Jack talks about his time spent making clay pipes. He remembers how hard the work was, in particular, after a break. 'But we hardly ever worked on a Monday,' he recalled. 'If you worked day in day out it wasn't so bad but once you had a day off, it took a bit of starting again. After a day off I felt terrible. It must have been the foistiness [his word] of the place - the damp clay, the smoke and the fumes.'

'Way back, some of the public houses kept ten or twenty gross of clay pipes ready for giving away,' Jack remembered. 'On Teesside they were the T.W. type (named, Jack believed, after a Thomas White who designed the type). They were the most popular in the Teesside area. The Turf Hotel in Cannon Street gave two gross away every week. In fact, they gave away a gross every Sunday night.' At the time the article was written, Jack had some pipe moulds left but had given all his pipes away during World War Two, when pipes were hard to obtain.

Evidence that Jack continued to make pipes well into the 1930s comes in the form of an order from Ralph Barton and Sons of Hetton-le-Hole, Co. Durham. The order was sent to Stowe Street but addressed to Jack rather than his father. The Armstrong family did not move to Stowe Street until 1937.

Jack holding Martin Jack's grandson, Martin Pickering, wrote of Jack's family in 1991, 'They lived at 66, Harford Street then moved to Parliament Street where they had a general dealer's shop. They moved to Leinster Road and converted their corner house into a shop. Jack sold haberdashery-wool, cotton, dishcloths etc. and pipes from the shop but also drove many miles by car selling his goods.' Martin has fond memories of Jack, 'I remember my grandfather, Jack, as a wonderfully generous man. He would do anything for anyone and was a marvellous handyman.'

Jack's daughter, Raye, writing in February 2008, recalled her father's pipe making days, 'I sometimes went into the countryside when he delivered clay pipes, briar pipes and haberdashery to shops in mining villages and inns. When dad travelled in the Scottish Borders he went alone or with Harry and they stayed overnight. I remember we went to Buttertubs and the name always intrigued me.'

'My dad and others had built a big garage behind our new house at 39, Leinster Road and it was lined on three sides with shelves where the wooden boxes of clay pipes, packed in wood shavings were stored ready for delivery. There was also a workbench where dad would paint the ends of the pipe stems with red shellac so the smokers' lips didn't stick to the pipe stems. Some of the pipe bowls were designed like heads or a boot toe cap with a small football attached. One of the bowls was a man's head in a straw hat and he had a long nose which was painted with red shellac. He was called 'Nosey Parker' (36). Each pipe stem had a red oval gummed label stuck round it, bearing the Armstrong name. Every one licked by my dad! Dad would pack the boxes in the car in the evening [Lena remembers that a horse and cart was used to deliver the pipes manufactured in Marsh Road until Jack was able to buy a van] and cover them with a big rug ready to set off early the next day. At the time the car had a big white painted wooden pipe mounted on the roof'.

As a young man, Jack fought in the Great War. He followed his father, John, into the Yorkshire Regiment in 1917. Raye remembers that he was sent to Russia when his regiment took part in the fight against the Bolsheviks. Jack was a popular and respected member of the Armstrong family and was best man at his brother Fred's wedding in 1951.Jack died on 21 January, 1971.

8: Robert Henry (Harry) Armstrong (1900-1981)

Robert Henry was always known as 'Harry' and was the second son of John (b.1872). He was born in Middlesbrough on 14 August, 1900. He also joined the family business of pipe making and it is for his role as a salesman that he is particularly remembered. Lena recalls him travelling to local pubs carrying samples of Armstrong pipes. Harry married Louisa Horton (b.1902), daughter of James Horton, on Christmas Eve, 1925. On the marriage certificate Harry's occupation is given as 'pipe manufacturer'. They had one son, James Henry (also known as Harry), in 1927. On the birth certificate Harry's occupation was given as 'pipe maker'. Following the decline of the pipe making business Harry found work at the steelworks in Middlesbrough.

Fred's wife, Mary, and Lena both remember Harry (senior) fondly as a jovial character. He was good company and they enjoyed their visits to his home in Middlesbrough. Harry died on 1 April 1981, aged 80.

Notes

(1) See Marie Hartley and Joan Ingilby 'Life and Tradition in the Moorlands of North-East Yorkshire' p.96-102.

(2) See 'Fred's 100-year-old clay pipe industry reappears' in The Northern Echo 3 May 1972.

(3) Martin's research and photos taken when Rex 'discovered' the pipe moulds in Stowe Street can be found at www.yourbook.co.uk/hobby/pipes/index.html

(4) See www.thebookofdays.com

(5) Adrian Oswald 'Clay Pipes for the Archaeologist' (1975) Ch. 2

(6) Ibid p.7 Oswald refers to a letter (P.R.O. ref. S.P.14/98) quoted by I.C. Walker in his paper 'Some notes on the Westminster and London Pipemakers' Guild', Trans. London and Middlesex Archaeological Society, 23, Pt.1 1971.

(7) Lloyd Edwards writing in 'The Archaeology of the Clay Tobacco Pipe XI (1988)' records John Armstrong, a tea and tobacco dealer in the Tollbooth district of Gateshead 1790-1795 (p.121) and cites references from Whitehead's Directories for 1790 and 1795 (see Appendix 2). He provides some evidence to link tobacconists to pipe makers (p.116-118). 'There are four possible examples of (Gateshead) pipe makers and (Newcastle) tobacconists being related. It is possible that some of these may represent entrepreneurial families attempting to widen their commercial horizons and influence. The best example might be that of the wealthy tobacco-merchant Edmund Middleton putting a member of his family into the pipe making trade.' The idea of a link between James and this John Armstrong is appealing! However, the weight of evidence is probably against a connection. In general terms tobacconists tended to be relatively wealthy, pipe makers relatively poor. As Edwards puts it, 'although the evidence is limited, it would seem reasonable to suggest that tobacconists and pipe makers, although dealing in very closely connected commodities, were (certainly in the late seventeenth and early eighteenth centuries) in very different financial strata of society.' Other research suggests that the situation was still true in the late eighteenth century.

In the specific case of James, only one James Armstrong was baptised in the St. Mary's parish of Gateshead (which included the Tollbooth district) in the period 1792-1800 and his father was a mariner. A James Armstrong was baptised on the other side of the River Tyne in the All Saints parish of Newcastle on 7th May 1795. Unfortunately his father, Thomas did not have his occupation recorded in the baptism register, or indeed in the marriage register when he married Ann Mills in 1785, so I cannot link him to the tobacco industry. Given the evidence currently at my disposal I tend to the opinion that the Stokesley baptism reference (below) is the more likely of the two (but of course I cannot be sure!)

(8) The 1841 census states that James was born in England but outside Durham, his county of residence at the time. If the age given on both the death certificate and the burial record are correct then James was born between 10 April, 1794 and 9 April, 1795. The only local baptism record for this period I have found so far, outside Durham, is in Stokesley, North Yorkshire on 23 November, 1794. This James had no father's name on the baptism record and the mother was given as Ann Armstrong, spinster. No siblings were baptised from 1780-1800 in Stokesley or its neighbouring parish, Seamer-by-Stokesley. A search of registers in both parishes has revealed neither a marriage reference for James for the years 1812-1837 nor a death or burial reference for the period 1794-1870. This suggests that this James did leave the area. The most likely baptism record for Ann gives a baptism date of May 8 1774 in Seamer-by-Stokesley.

A cautionary note needs to be sounded at this point, since the death certificate and 1841 census transcript provide conflicting evidence regarding James's age. The census gives him the age of 40 and, given the custom was to round ages down to the nearest multiple of 5, he could have been any age from 40 to 44. The census took place on the evening of June 6 but when James died less than a year later, on the ninth of April 1842, his age at death was given on the certificate as 47! The note above is clearly based on the assumption that the death certificate is accurate. However, if I were to suppose that the census was correct, then James could have been baptised anywhere in England, outside Durham, from 1796-1801. There are numerous baptism references for James Armstrong recorded on the IGI for this period. However, it is possible to narrow the focus of the search by checking only those references which occurred in known pipe making areas. Unfortunately, since none of these records gave pipe making as the father's occupation I have no evidence of a link to my family.

(9) A search of the Apprenticeship Books (IR 1) in the National Archives in Kew, Surrey gave no reference to an Armstrong as a master or an apprentice in the pipe making trade 1775-1811 in any part of England. Additional checks of locally held records for North Yorkshire, Durham and Northumberland also provided no references to Armstrong pipe makers or apprentices for the same period.

Peter Hammond, writing in the SCPR newsletter no.65, gives a full list of all the tobacco pipe makers mentioned in the Inland Revenue Apprenticeship Books from 1763 to 1810. No reference to an Armstrong pipe maker is included.

(10) The other avenues of research I have pursued so far have not resulted in any links to James. I have found no other Armstrongs with the occupation of pipe maker in the 1841 census, suggesting James had no brothers making pipes at this time. I have found no Armstrong pipe making references at all pre-1820 in the National Clay Tobacco Pipe Association (NCTPA) archives. A search of Phillip Woollard's unpublished 'List of [certain] Clay Tobacco Pipe Makers' c.1799-c.1846 compiled from Guildhall Library manuscripts 2821, 3601 and 3817 (1999) produced no references to James Armstrong or any individual with the surname Armstrong.

So far every reference to an Armstrong pipe maker I have found in any census 1841-1901 has been James or one of his direct descendents.

(11) Sarah's exact birthplace and baptism date are uncertain, however, it is very likely that she was born on 2 March and baptised on 8 July 1792 in the parish of St. Thomas, Stockton on Tees. Sarah's parents were John Hunter, cowkeeper, native of Marwood Park in the parish of Barnard Castle, Durham and Sarah Smith, native of Thimbleby in the parish of Osmotherley, North Yorkshire.

(12) 'The Archaeology of the clay Tobacco-pipe in North-East England' by J.E. Parsons in Archaeologia Aeliana 4 XII page 249-254 gives the following pre-1850 Stockton pipe makers; John Andrew (1847) from Whellan's Directory, George Sephton (1847) from White's Directory and Thomas Sephton (1841) from Robson's Directory. The 1841 census lists several pipe makers operating in West Row, Stockton, including John and George Sephton, James Siddle, George Bell and William Buerly.

(13) Hannah Siddon was a widow when she married James.She was born Hannah Smith c.1800, the daughter of Thomas and Mary Smith. Her first marriage was to Daniel Siddon (born c. 1794), in the St. Werburgh parish of Derby, on 12 May 1818. In the marriage register, Daniel's occupation was described as 'soldier in the 95th Regiment of Foot'. She had four children with Daniel, Mary Ann b. 1819, Catherine b. 1822, William b. 1823 and Daniel b. 1825. Sadly, Mary Ann died in 1820 at the age of 5 months and Catherine died in 1823 at the age of 14 months. It is very possible that the two boys also died young since I can find no record of them in either the 1841 or 1851 census. Daniel Siddon died in 1826 at the age of 32.

(14) Willow Row was an important location for pipe making in Derby. Pigot's Directory (1835) gave the following pipe makers as working in Willow Row; William Cleever, Jonathan Salisbury and Son and Thomas Strong (the brother of James's Employer) who was listed as based at Court no.7. Several pipe makers were working in Willow Row at the time of the 1841 census, including three members of the Strong family, Samson, Thomas and Samson's young son, also called Thomas. In addition, James Wallis, John Stuart and John Heath were also listed.

(15) Ann was born c.1793 in Shildon, Durham. When she married James she already had a son, George (1819-1884) who eventually became a non-conformist minister. Ann did not remarry and died on 5 February 1875 at the age of 82.

(16) Mary James was born in Brandon, Durham on 16 April 1812 and baptised four days later in Haughton-le-Skerne. She was the daughter of William James, a woolcomber (c.1784-1860), and Elizabeth, formerly Lamb (c1788-1815). Mary was married to William Chaytor (1811-1835) in Darlington on 12 December 1830 and had three daughters, Mary Ann b. 1831, Elizabeth b. 1834 and Jane b. 1835. Mary had two half-brothers who manufactured clay pipes. After the death of Elizabeth, William married again to Mary Stephenson on 18 May 1822 in Darlington and two of their sons became pipe makers. They were both recorded as working in Darlington as pipe makers in the 1851 census. Richard, born c.1831 made pipes in early adulthood and probably worked for John Armstrong (1822-1871). He then changed occupation, becoming a butcher. Joseph, born c.1834 spent most of his working life as a pipe maker. He started his pipe making career in Darlington and, again, his likely employer was John Armstrong. Following the closure of the Armstrong workshop in Station Street, Joseph moved to Macclesfield. In the 1891 and 1901 censuses he was recorded as working as a pipe maker and residing with George H. Turpin, a pipe manufacturer. Adrian Oswald in 'Clay pipes for the Archaeologist' (1975) lists several members of the Turpin family of pipe makers (p.162). He gives the source of the references as G. C. Spence 'Chester Pipes' (1941).

(17) Sarah Jane Tutin was baptised on 21 February 1832 in Kirby Sigston, Yorkshire. After John's death she married a grocer, John Allison (1878). Sarah died in 1885 aged 52.

(18) Annie Hewitt was born on 15 July 1852 in Howden, the daughter of James (1825-1879) and Sarah Hewitt, formerly Jackson (1824-1902). Annie herself was involved in pipe making and was described as a 'tobacco pipe finisher' in the 1881 and 1901 censuses. Annie also spent time periodically in the Middlesbrough workhouse between 1900 and 1904, although she was a less frequent visitor there than her husband. She lived for a time in Sunderland and was recorded as a 'pipe finisher' who was working 'on her own account' in the 1911 census. In principle, this meant Annie would not have been tied to one employer but in practice she is likely to have worked in one or two local workshops. She would have been paid according to the number of pipes she finished. (I am very grateful for the information provided by Peter Hammond and David Higgins concerning the piece rate payment methods for pipe finishers). At the time of the census, Annie was resident at 15 Nile Street, an address near to her son, John. Her youngest son, William, aged 17 was living with her. In true Armstrong tradition he was described as a 'pipe maker', although it is interesting to note that he was described as working 'not on his own account'. This suggests that he was employed by a specific master pipe maker: quite possibly his elder brother, John.

Annie did not remain in Sunderland long. She moved back to the Middlesbrough area and died on 20 March 1915 while resident in Eston. Like her husband, she died at 23, Eston Grange, the home of their daughter, Annie.

(19) The extract was included in 'The History of Thornaby', published by Teesside County Borough in 1970.

(20) A letter sent from Preston Hall to David Higgins in 1993 contains this information but does not name the particular directories. There is also a reference to a J. Armstrong, pipe maker, of Thistle Green, Stockton. This could be either John (b.1849) or his son (b1872). It is more likely, although not certain, to be the former. The younger John was resident at a different address in Thornaby in December 1898, when his son, Jack, was born. I have no information about the residence of the elder John between 1893 and 1901.

(21) Extensive research of the workhouse and children's home records in Middlesbrough has revealed numerous entries for the Armstrong family during the period described, however they tended to stay in these institutions for short periods, leave and then be readmitted. Indeed, the three youngest children were admitted and discharged within three days in September 1900.

(22) Jessie Teasdale was born in Stockton on 1 January 1873. Her mother was Mary Ann Ferguson Brown (1850-1918) but no father's name was given on the birth certificate. When Mary Ann married William Foster Teasdale in 1874 Jessie's surname changed to Teasdale. Jessie had one brother, George William (1870-1941), and six more children were born to Mary Ann after her marriage. Both Jessie and George William (Bill) spent a lot of their early days living with their grandmother, Emily Curren (nee Grummett, who married twice, to Joseph Brown in 1839 and James Curren in 1867). Emily was born in Norfolk in 1819 and lived until 1908. She died, aged 88, while resident in the Middlesbrough workhouse. Jessie was described as 'straight-laced' by Lena and it seems clear that she was greatly saddened by the loss of Jessie, Eddie and Alfie. Following Alfie's death (he was found drowned in the Thames during World War Two), Jessie became increasingly difficult and appears to have been particularly harsh on her husband, John. Jessie died on 26 November 1953, aged 80, whilst staying with her daughter, Annie.

Jessie, pictured with her son, Fred, shortly before her death

(23) The pipe makers given for Newcastle in Kelly's Directory (1896) were J. Collier of Prudhoe Place, Nugent and Co. of Vincent Street and William Tennant of Pilgrim Street.

(24) D. Helme in 'The Clay Tobacco Pipe' (1978) refers to this company and remarks that 'in its heyday there had been sixteen skilled pipe makers in the factory' (p.50)

(25) Ibid (p.52) for some reason calls John by the wrong name - James !

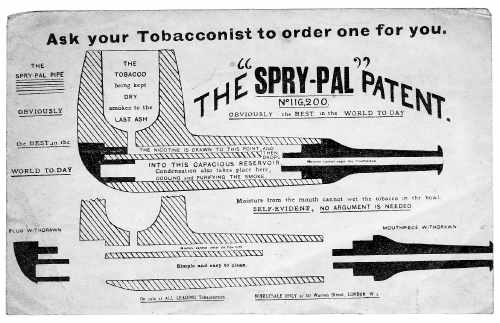

(26) Ibid (p52). I have been unable to confirm the nature of John's 'invention'. However, amongst his papers I did find a label referring to 'The Spry-Pal' patent. Evidently, the 'Spry-Pal' pipe was made using a plug such that 'moisture from the mouth cannot wet the tobacco in the bowl'. The Spry Pal has the patent number of GB116200 but, unfortunately, the product was not patented by John! The patent was registered by James Spry-Palmer on 6 June 1918 (see Appendix 5).

(27) Ibid (p54)

(28) The title of the article was 'Snobs Scorn the Clay-Pipe, Church-Warden out of Fashion'. The original copy of this article has since been lost. However, a typed copy was made by a family member and dated April 1928. A search of local newspaper archives for this date failed to reveal its source.

(29) Walter John Bagshaw was born in Greenwich in 1857. He was the son of William Bagshaw (1822-1891), a tobacco pipe mould maker, gun maker and whitesmith. William's father was Joseph Bagshaw, a gunsmith. William, at least as young man, worked as a pipe mould maker. He was described as a 'mould maker', working in Lewisham in the 1851 census. However, when William married in the same year he was described as a 'gunmaker', indicating that he was not a pure specialist in either activity. William's wife, Emma, was the daughter of Thomas Ruscoe, a clay pipe maker.

In the next two censuses, 1861 and 1871, William was based in Greenwich and working as a 'pipe mould maker'. His next door neighbour in Grove Street, in 1861 was William Doubtfire, a clay pipe maker. It is interesting to note that one of William's brothers, Edward (1834-1905) also made pipe moulds. In 1851 he was living in Greenwich and was described as a 'pipe mould maker'. However by 1861 he had changed his occupation and become a carpenter. Julian Bowsher, writing in SCPR newsletter no.72 (p.35-46) on the subject Greenwich tobacco pipes, refers to the Bagshaw family and William Doubtfire.

In the 1881 census, both William and Walter were recorded as working as whitesmiths. By 1891, William was a retired whitesmith but Walter was still operating in the trade. However, by the time of the 1901 census, Walter had returned to his father's original occupation and was described as a 'tobacco pipe mould maker', working on his own account.

The surviving quote shows that Walter was also involved with other activities ('gas stove fuel' was mentioned in the letter heading) but it is interesting to note that he considered the making of tobacco pipe moulds to be his major occupation. His residence was 176, Edward Street, New Cross, London and his workshop was located nearby, at 171, Edward Street. He is listed as a clay tobacco pipe mould maker, operating at this address, in Post Office London Directories from 1895 to 1918. However, the label attached to an order sent to John Armstrong indicates that he was still doing some trade after 1924. When Walter died in 1935 he was described as a retired pipe mould maker on the death certificate. Phillip Woollard provides more details regarding the Bagshaw family in SPCR newsletter no.55, including census transcripts and rate book references.

Edward Street, 1895, showing old house and mulberry trees

(30) Hugh Herriot was born c.1879 in Glasgow. He was described as a 'tobacco pipe mould maker' in the 1901 census and his address was 54, John Knox Street. The receipt sent to John Armstrong shows he was still selling pipe moulds in 1932, by which time he was based at 64, Abercromby Street. Hugh's father, James Herriot (born c.1845 in Glasgow), was also a tobacco pipe mould maker and was listed as accordingly in the 1881, 1891 and 1901 censuses. He was resident at 54, John Knox Street in all these censuses and recorded as a 'tobacco pipe mould maker', based at this address, in Post Office Directories for Glasgow from 1880-1920.

(31) The deposits of ball clay found in Devon proved a useful material for the manufacture of tobacco pipes from the seventeenth century onwards. In 1879 William Wren established The Marland Brick and Clay Works Ltd in North Devon. The North Devon Clay Company Limited took over the business in 1893. It engaged in clay mining and sold a variety of different types of clay, using the deposits of ball clay lying between Great Torrington and Hatherleigh in North Devon. (A detailed study of the ball clay industry can be found on the web site of The Ball Clay Heritage Society, www.clayheritage.org)

(32) Helme in 'The Clay Tobacco Pipe' 1978 (p.34) notes that they were making pipes around 1910.

(33) Ibid (p.38) states that 'of all the styles of clay pipes produced over the last one hundred years, the one theme which stands apart covers those clays manufactured for Royal Antediluvian Order of Buffaloes.' Helme considers that 'for sheer mass of variation in design this classification is totally unsurpassed.' He remarks on the range of ornamentation being 'from a complete buffalo's head forming the bowl or the spur to a simple horn motif with the letters RAOB.'

(34) An interesting photograph of a pipe commemorating General Gordon can be seen in Eric Ayto's 'Clay Tobacco Pipes', Shire Books, third ed. p.17.

(35) Hannah Mary Weatherill was born in Danby, North Yorkshire on 2 September 1920, daughter of Jack and Emily Weatherill. Jack came from a long line of stonemasons and quarrymen. He was also a local historian, poet and violinist. After leaving school, Mary worked in service for a Harley Street doctor who had a country residence in Danby (which had been built by her father). She spent most of the war years working in the land army in Kent. After the war she returned north and worked in Middlesbrough. After marrying Fred she lived with him in Stowe Street, a location that was to become her home for the next 53 years. Mary remained creative and humorous and, like her father, enjoyed poetry!

Fred and Mary on honeymoon in Morecombe in 1951 Mary pictured at Preston Hall Museum in the late 1970s. A display of Armstrong pipe moulds can be seen behind her. The receipts from the North Devon Clay Company (31) and Hugh Herriot (30) (upper frame) and the quote from Walter Bagshaw (29) and two postcards from Ralph Barton and Son (lower frame) were part of the exhibition.

(36) For an example, see Eric Ayto's 'Clay Tobacco Pipes', Shire Books, third ed. p.17.

I have no photographs of my great grandfather and no information about his character or his likes and dislikes. However, censuses, trade directories and the birth certificates of his children give me, at least, little snapshots of his life. I would like to know more about him as a person but I will have to be satisfied with what I have.

Fortunately, I have plenty of photographs and information about my grandfather. He remains a fascinating individual, hard to categorise and seemingly full of contrasts. He was described by my own father as harsh man, prone to drunkenness. However, my dad also spoke highly of his father's skills as a pipe maker and the way he ran his business. He admired John's athletic abilities and his role as the dominant force in the family.

John was certainly a well known pipe maker, featuring in at least three newspaper articles, and his surviving letters show that he could write well and with style. He was also a very brave man, who, in October 1914, at the age of 42, left his home and business to fight in the Great War. John spent 3 of his 5 years of military service in the field, my dad remarking that he went 'over the top' nine times. He did well to survive. I don't know how the war affected him or indeed, if the more unpleasant aspects of his behaviour were in any way linked to his wartime experiences.

My own father was a gentler, less dominant figure, with a cautious nature. He too, spent 5 years in the armed forces. When I reflect on my own life I can't help but feel proud of my father and grandfather and very grateful for the fact that I haven't had to leave my home and family to fight in a war.

If John was right, when he was interviewed in 1928, I might have inherited some pipe making talents. However, the unbroken line stretching back five generations of Armstrong pipe makers ended with my father and I think my working life has been a lot easier than my predecessors!

APPENDIX 1

The Hewitt Family of Clay Tobacco Pipe Makers

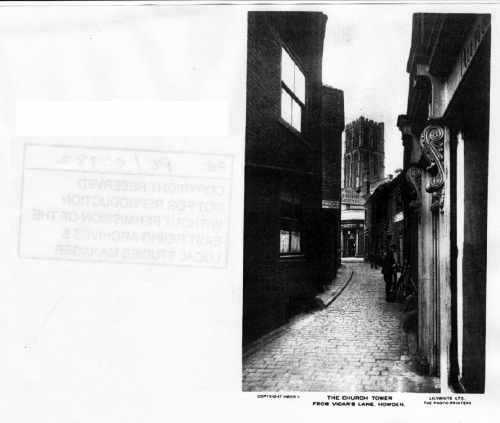

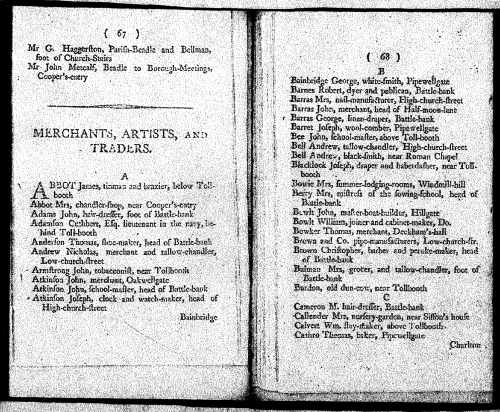

James Hewitt was baptised on 19 March, 1825 in Hemingborough, Yorkshire. He was the son of a miller, James Moody Hewitt (1799-1825). James was the first of many Hewitt pipe makers. The Hewitts were much more geographically mobile than the Armstrongs and James's sons and grandsons worked in several towns and cities in England. James was recorded as a pipe maker in all the censuses from 1841 to 1871. In the 1841 census he was aged fifteen and residing in Howden with Elizabeth Thompson, a pipe maker. By 1851, he had become a 'pipe maker-master' and was still working in Howden, residing in Vicar Lane (see below). Interestingly, his widowed mother, Hannah, a milliner, was described as the head of the household. Both Elizabeth and James were recorded as tobacco pipe makers (the only two in Howden) in Slater's Directory for 1848 and 1855. Elizabeth had premises in Northolmby Street and James had a workshop on St. Helen's Square, a location very close to his home.

Vicar Lane, Howden, circa 1905

Evidence from the birth certificate of his second son, Henry, shows that by 1857 James was living in Darlington and was working as a pipe maker there. He then moved to Hampshire and his daughter Minnie was born in Gosport. The Portsmouth area was an important area for pipe making from the seventeenth century to the early twentieth century (see 'The Clay Tobacco Pipes of the Portsmouth Harbour Region 1680-1932' by R.T. Fox and R.B. Hall 1979) and it is very likely James continued to work as a pipe maker whilst living there.

James then returned to Darlington and by 1861 he was living in Bondgate and was described in the census as a 'pipe maker.' The next household on the register was that of James Furniss, pipe maker. (Several Furniss pipe makers were working in the mid nineteenth century. In addition to James, Henry and William worked in Darlington. The latter is recorded in White's Directory for 1847-1864. Francis Furniss was working in 'Ferry Boat Landing', Thornaby at the time of the 1851 census. Four other pipe makers, Edward Barnes, Peter Row, John Andrew and Henry Kelley lived in neighbouring properties).

In the 1871 census James was recorded as living in Station Street, Darlington and he was very likely to have been working for John Armstrong at this time. James and Sarah Hewitt, Joseph James (see note 16) and John and Annie Armstrong were living in adjacent dwellings! James died on 1 January 1879.

James's two sons, Thomas (1847-1906) and Henry (1857-1925) were both pipe makers. Thomas worked in Darlington, Nottingham and London. In 1868 Thomas married Margaret Hindle in Darlington. They had two sons Thomas (b.1868) and James (b.1870). At the time of the 1871 census Thomas was working as a pipe maker in Darlington and living in Bowker's Yard, Bondgate. By 1881 he had moved to London, living at 22, Jodrell Road and was described as a pipe maker. The census records Thomas as living with a second wife by this stage although I can find no evidence of the marriage. The second wife, Matilda (probably born with the surname Stevens) was described as a 'pipe trimmer'.

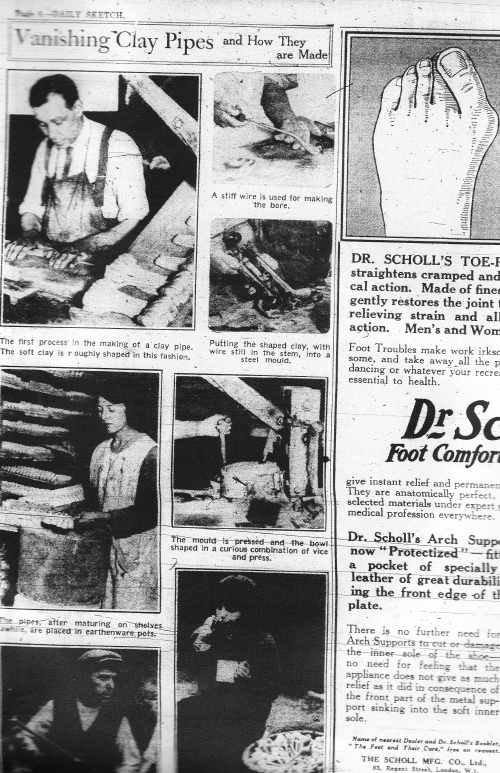

It is interesting to note from this census that Thomas's second son James, aged 11, was living away from home at the time. He was described as a 'visitor' residing nearby with Hannah E. Reynolds a 'tobacco pipe maker employing 20 men, 2 boys, 2 women and 8 girls' at 245, Old Ford Road, London (see below). It seems certain that Thomas was in her employ at this time. Hannah was the widow of John George Reynolds and in the Post Office Directory for 1882 the business was still listed under his name. The directory contains the following entry for John, 'export pipe maker (1000 shapes and sizes), patterns made to suit the colonies'. In the 1895 Post Office Directory Hannah is recorded as the proprietor of the business which occupied both 243 and 245, Old Ford Road. By 1900 the business had been taken over by Edward Back, John Reynolds' son-in-law. The 1915 post Office Directory contained the following entry for Edward, 'plain and fancy clays, long and short for home and export, 'Burn's Cutties', 'Ben Nevis', 'Gladstones' & 1000 other shapes'. It is very likely that Edward Back's business was the unnamed Old Ford Road firm featured in an article in the Daily Sketch on 8 April 1926 (see below).

In 1881 census, Thomas's brother, Henry, was also living at 22, Jodrell Road but with a different head of household, Alfred Reynolds, who was described as a commercial clerk in a pipe factory. Henry would also have worked for Hannah Reynolds. Alfred was the son of John George Reynolds and his first wife, Lydia. He worked as a commercial clerk at the Old Ford Road workshop, firstly for his father and secondly for Hannah, John's second wife, when she took over the business. Interestingly, in the 1871 census Alfred was recorded as a 'pipe case maker' boarding with Charles Phillips, a pipe maker, in Holborn.

Thomas and his eldest son left London and by 1891 both were working as pipe makers in Nottingham. According to the 1891 census, one of Thomas's neighbours in Robin Hood Yard, Milton Street, was Walter Daft, a 'pipe manufacturer'. (R.C. Alvey's list of pipe makers for Nottingham in Adrian Oswald's 'Clay Pipes for the Archaeologist' gives several members of the Daft family, including Walter). Thomas's death certificate confirms that he worked as a journeyman pipe maker so it is quite possible Walter was his employer. At the time of the 1901 census, Thomas was still living in Nottingham and was described as a 'clay pipe maker'. He died in 1906, aged 59 but Matilda continued to work in the industry. In the 1911 census she was recorded as living in Keswick street and working as a 'tobacco pipe finisher'.

Thomas's son, Thomas, worked in the same location as his father. Evidence from his marriage certificate (he married Alice Hudson in 1891) and the birth certificate of his daughter, Alice, born in 1892, show that he was a pipe maker working in Robin Hood Yard. It is likely that he worked for Walter Daft like his father. Thomas was still working in Nottingham in 1896 but he had moved to London by 1899. When his son, John, was born in January of that year he was living at 67 Palmerston Road in East Plumstead and would have been in the employ of William Luckett (see 'William Luckett, Clay Tobacco Pipe-Maker of Plumstead' by Phillip Woollard, Greenwich Industrial History, volume 5 issue 6 November 2002). However, by the time his daughter, Minnie was born in December 1900 he had given up pipe making and in the 1901 census he was recorded as a 'cordite ammunition cartridge maker'.